Siemens Opcenter APS 18

Benefits

• New Siemens Opcenter APS

product branding

• Additional APIs for interacting with

advanced highlight and filtering

tools

• Extended Siemens Opcenter

Scheduling Anywhere upload to

include facility information

• Compatible with Siemens Opcenter

Execution Discrete 3.0 and 3.1

Features

• API for interacting with advanced

highlighting and filtering results

• Facility definition with Siemens

Opcenter Scheduling upload

facility

• Supports integrations to Siemens

Opcenter Execution Discrete 3.1

and Valor® Production Plan 14.1

Summary

Siemens Opcenter APS (formerly known

as Preactor APS) software is a family of

production planning and scheduling

products that improve the synchronization of your manufacturing processes,

giving you greater visibility and control

and enabling you to increase resource

utilization and on-time delivery while

reducing inventory levels and waste.

Siemens Opcenter APS is a highly customizable capacity planning and scheduling package.

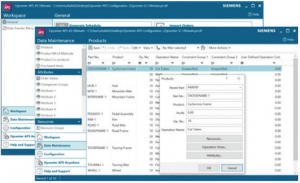

Preactor APS becomes Siemens Opcenter APS

Preactor APS becomes Siemens

Opcenter APS with release 18, with

aligned icons and desktop.

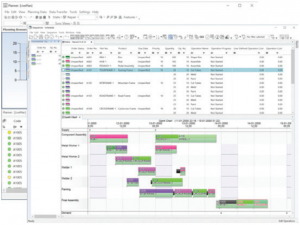

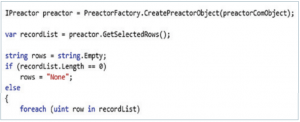

Additional APIs for advanced

highlight and filtering tools

Additional application programming

interfaces (APIs) have been added to

the already extensive API library of

Siemens Opcenter APS, allowing extensions to be implemented with ease.

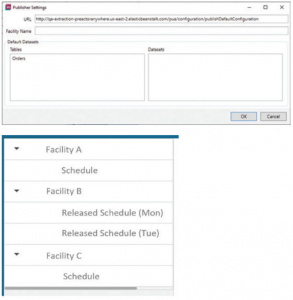

Siemens Opcenter Scheduling

Anywhere facility upload support

Siemens Opcenter Scheduling

Anywhere upload now supports the

ability to define a facility name, allowing users to separate facility uploads for

multiple sites.

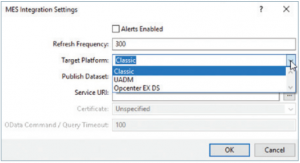

Integration with Siemens Opcenter

Execution Discrete 3.0 and 3.1

Available only for Siemens Opcenter

Scheduling (Siemens Opcenter SC)

Ultimate, Siemens Opcenter SC integrates with Siemens Opcenter

Execution Discrete with an out-of-thebox integration between the manufacturing execution system (MES) and

advanced planning and scheduling.

Integration with Valor Production

Plan 14.0 and 14.1

Valor Production Plan software creates

an easy-to-use yet comprehensive

model that allows you to simulate your

production process including all surface

mount technology (SMT) and manual

stations. You can set optimization

parameters such as due date, production time and changeover that enable

you to make intelligent choices

between given plans that fit your exact

needs to meet deadlines and avoid

downtime.

Read more here