Opcenter Scheduling Standard is designed to be easily integrated with other business system to allow the simple retrieval of any required data, be that works order information from your ERP/MRP system or updates on operation progress from an MES of SFDC system.

The flexibility of Opcenter integration tools and data set up makes it possible to implement the system entirely stand alone, have it fully populated by data from other business systems or any scenario in-between.

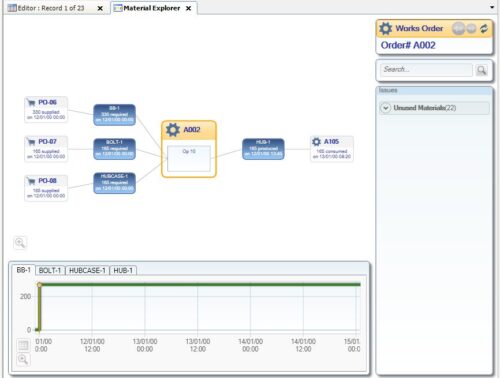

Opcenter Scheduling Standard is an “out of the box” solution. It uses order based scheduling to which the user can apply a ranking or weighting in order to prioritise the orders. It schedules based on availability of resources, additional constraints and the materials required for the order.

During the scheduling process Opcenter Scheduling Standard can take into account different operation run speeds on different resources, use sequence dependent changeovers times based on operation attributes and allow overlaps and slack times between operations.